KYN61-40.5 (Z) type armored movable AC metal enclosed switchgear (hereinafter referred to as switchgear) is a complete indoor distribution device with a three-phase alternating current of 50Hz and a rated voltage of 40.5kV. As a power plant, substation, and industrial and mining enterprise receiving and distributing electricity, it has functions such as control, protection, and monitoring of circuits, and can also be used in frequently operated places.

This switchgear complies with standards such as GB/T11022-1999, GB3906-1991, and DL404-1997.

Main features

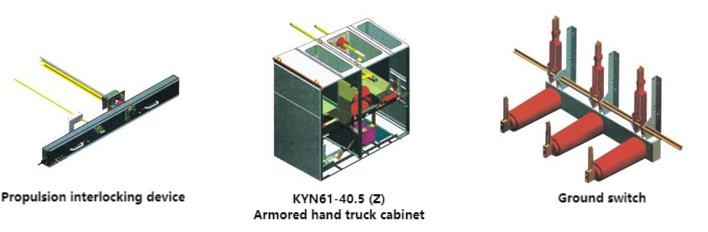

1. The cabinet structure adopts an assembled type, and the circuit breaker adopts a handcart floor structure;

2. Equipped with a brand new composite insulated vacuum circuit breaker, with the characteristics of good interchangeability and easy replacement;

3. The handcart frame is equipped with a screw nut pushing mechanism, which can easily move the handcart and prevent accidental operation from damaging the pushing structure

All operations can be carried out with the cabinet door closed;

5. The interlocking between the main switch, handcart, and switch cabinet door adopts a mandatory mechanical locking method, meeting the "five prevention" function;

6. The cable room has ample space and can connect multiple cables;

7. Quick grounding switch is used for grounding and circuit short circuit;

8. The shell protection level is IP3X, and when the handcart compartment door is open, the protection level is IP2X:

9. The product complies with GB3906-1991, DL404-1997, and adopts international IEC-298 standards as reference

Environmental conditions for use

1. Environmental temperature: Upper limit+40C, and the average value measured within 24 hours does not exceed 35C, lower limit -10C

2. Altitude: The altitude shall not exceed 1000m.

3. Relative humidity: The daily average value shall not exceed 95%, and the monthly average value shall not exceed 90%.

4. Seismic intensity: not exceeding 8 degrees

5. Water vapor pressure: The daily average value does not exceed 22kPa, and the monthly average value does not exceed 1.8kPa

6. Surrounding environment: Places without fire, explosion hazard, serious pollution, chemical corrosion, and severe vibration

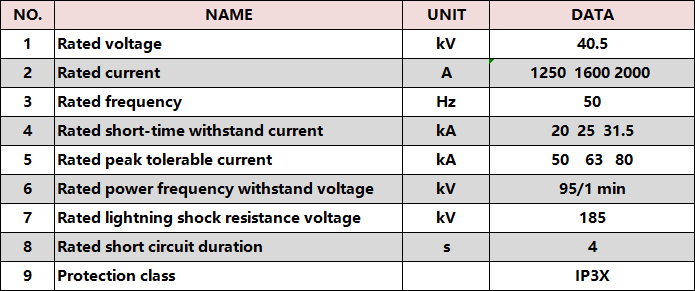

Vacuum switch cabinet main technical parameters

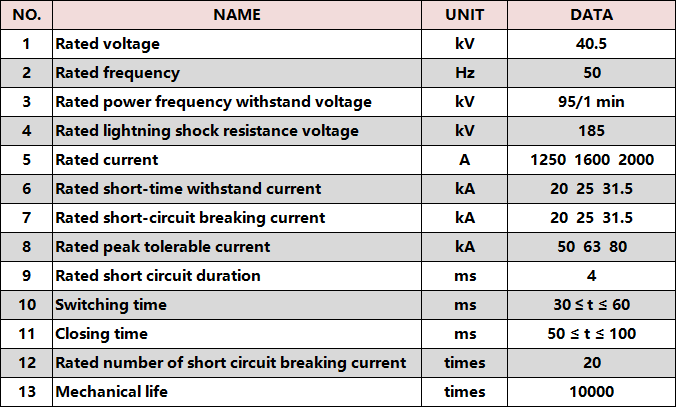

Vacuum circuit breaker main technical parameters

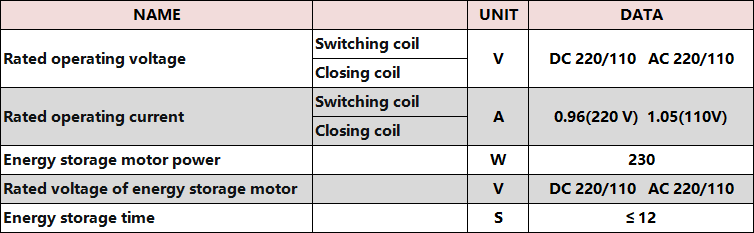

Spring operating machinery main technical parameters

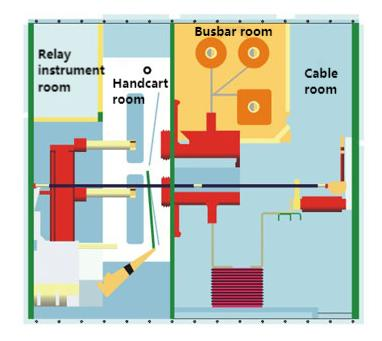

Structural characteristics of switchgear

The switchgear is designed according to the standards for armored metal enclosed switchgear in GB3906-1991 and IEC298. The whole is composed of two parts: a cabinet body and a withdrawable part (handcart). The cabinet structure is assembled and assembled with bolts for inspection and assembly. Use metal partitions to divide the interior of the switchgear into circuit breaker rooms, main busbar rooms, cable rooms, and relay instrument rooms. The shell protection level reaches IP3X, and the protection level between compartments is IP2X. All metal structural components are reliably grounded, and each compartment of the main circuit system has an independent pressure release channel for exhaust.

1. Shell and partition

The shell and partition of the switchgear are made of cold-rolled steel plates processed and bent by CNC machine tools, and then bolted together. Therefore, the assembled switchgear can ensure the uniformity of structural dimensions. The switchgear is divided into a circuit breaker room, main busbar room, cable room, and relay instrument room, with each part separated by a grounded metal partition.

2. Handcart

Handcarts can be divided into circuit breaker handcarts, voltage transformer handcarts, metering handcarts, isolation handcarts, etc. according to their use. Each type of handcart has the same external dimensions, and handcarts with the same use have interchangeability. The handcart has test/isolation positions and working positions inside the cabinet, and each position is equipped with interlocking devices to ensure that the handcart cannot move freely when in the above two positions.

3. Circuit breaker compartment

A specific track is installed in the circuit breaker compartment for the handcart to move. When the circuit breaker moves between the test position and the working position. The automatic opening or closing of the valve ensures that personnel do not touch charged objects. The handcart can be operated with the cabinet door closed. The position of the handcart inside the cabinet can be seen through the observation window, and any functional signs on the handcart can also be seen.

4. Bus compartment

The main busbar is fixed from one switchgear to another through branch small busbars and static contact boxes, and is fixed with busbars when passing through adjacent cabinet side panels. All busbars adopt composite insulation method.

5. Cable compartment

PT, grounding switch, lightning arrester, and multiple cables can be installed in the cable room

6. Relay room

Secondary elements such as control, protection elements, metering, display instruments, live monitoring indicators, etc. can be installed on the indoor boards and panels of the relay.

7. Interlocking device

The switchgear has reliable interlocking devices, effectively ensuring the safety of operators and equipment. When the grounding switch is in the open position, the handcart can only move from the test/isolation position to the working position; And the back door cannot be opened to prevent accidental entry into the electrified compartment. When the handcart is completely pulled out of the cabinet or when the handcart is in the testing/isolation position inside the cabinet and the grounding switch is interlocked and unlocked, the grounding switch can be closed; When the handcart is in the working position, the grounding switch cannot be closed. It prevents accidental closing of the grounding switch when energized and prevents the handcart from moving to the working position when the grounding switch is in the closed position. The new circuit breaker handcart can only be operated when it is in the test/isolation position or working position, and after the circuit breaker is closed, the handcart cannot move, preventing live loads from accidentally pushing and pulling the circuit breaker. Electrical interlocking can be installed between cabinets.

8. Grounding device

In the cable room, a separate 6 * 50mm grounding busbar is installed, which can penetrate adjacent cabinets and have good contact with the cabinet body.

Our friendly team would love to hear from you!